Novel On -Site On-Demand Sodium Hypochlorite Generation from RO Brine

Make money from RO Brine before throwing it away. Use RO brine, if available, for salt source and not your usual seawater or table salt to produce hypochlorite.

Our process avoids equipment scaling issues, provides salt cost savings, and consumes less power. Call us to know how.

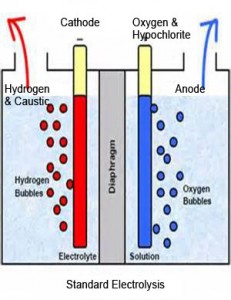

Malvi-tech offers a novel on-site on-demand Sodium Hypochlorite Generation from RO brine. Currently sodium hypochlorite is generated from two chloride sources: Manufactured salt and Seawater. Manufactured –salt- generated hypochlorite is used for disinfecting drinking water and Seawater- generated- hypochlorite for controlling marine growth in process equipment. This hypochlorite—seawater-generated– is not used for drinking water disinfection application because it’s bromate content far exceeds what is required to meet the stringent bromate standard currently set for drinking water application at <10 ppb. Process equipment scaling by calcium and magnesium present in seawater also is a serious issue with the seawater-generated hypochlorite, requiring frequent acid cleaning of equipment using hydrochloric acid, which is detested by most customers because of its hazardous properties, cost, and waste disposal issues.

Malvi-tech offers a novel on-site on-demand Sodium Hypochlorite Generation from RO brine. Currently sodium hypochlorite is generated from two chloride sources: Manufactured salt and Seawater. Manufactured –salt- generated hypochlorite is used for disinfecting drinking water and Seawater- generated- hypochlorite for controlling marine growth in process equipment. This hypochlorite—seawater-generated– is not used for drinking water disinfection application because it’s bromate content far exceeds what is required to meet the stringent bromate standard currently set for drinking water application at <10 ppb. Process equipment scaling by calcium and magnesium present in seawater also is a serious issue with the seawater-generated hypochlorite, requiring frequent acid cleaning of equipment using hydrochloric acid, which is detested by most customers because of its hazardous properties, cost, and waste disposal issues.

RO brine—the waste stream of Reverse Osmosis process used to make potable water from seawater—is not used for hypochlorite generation anywhere in the world in spite of its power saving potential—it has a higher electrical conductivity than the seawater or the salt solution made from manufactured salt– because relative to the seawater it has over 50% more bromide, calcium, and magnesium amounts, which compound the scaling and bromate issues to unmanageable levels, immensely countering its power advantage.

Malvi-Tech has a unique and novel process concept to produce on-site and on-demand hypchloroite from RO brine cost effectively—not currently done anywhere in the world. This hypochlorite can be used for either application—disinfecting drinking water or controlling marine growth in process equipment—obviating the need to use manufactured salt or seawater for chloride source, thus providing savings in salt and power costs while simultaneously mitigating the issue of equipment scaling and acid cleaning.

Process obviates purchasing and storing of manufactured salt, the process feature immensely attractive in some cases, such as ships, where the process currently used to generate hypochlorite necessitates storing large quantities of salt, increasing ship’s weight and space requirements, which is an anathema for ship operators, who are constantly seeking means to eliminate or reduce this burden.